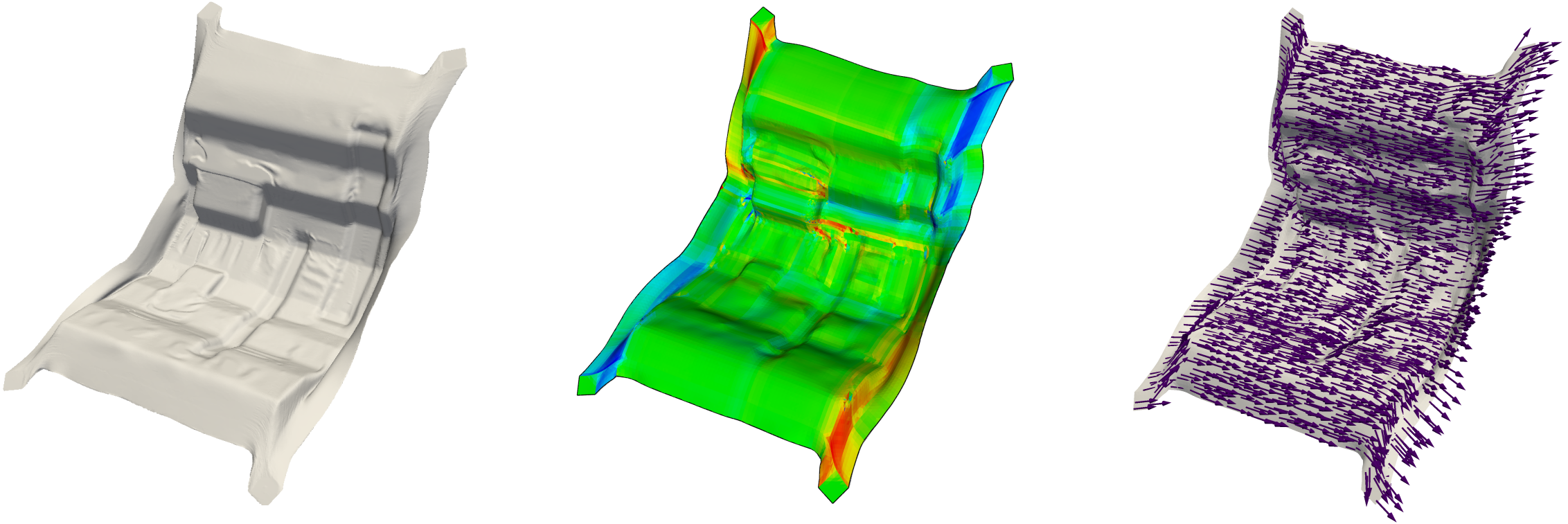

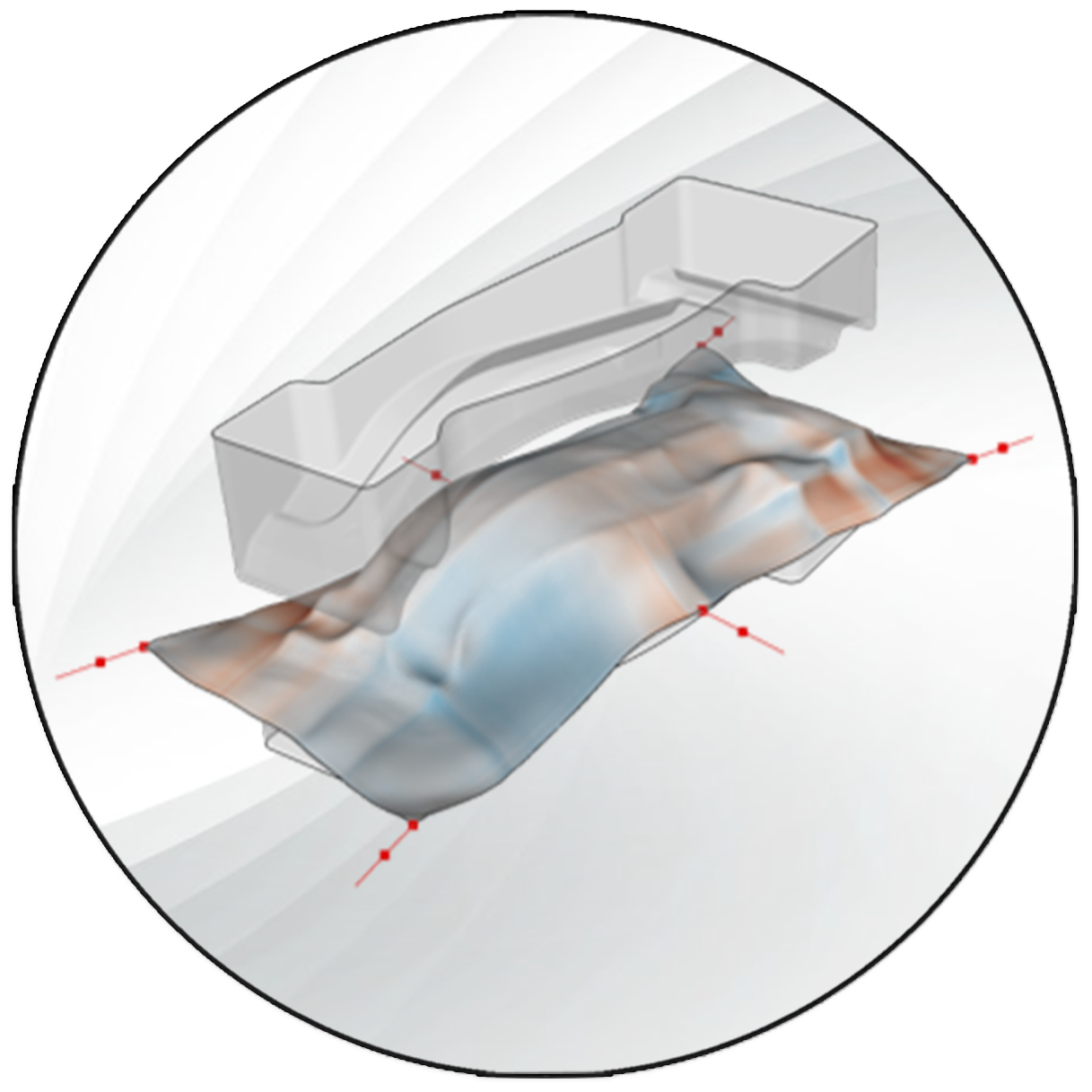

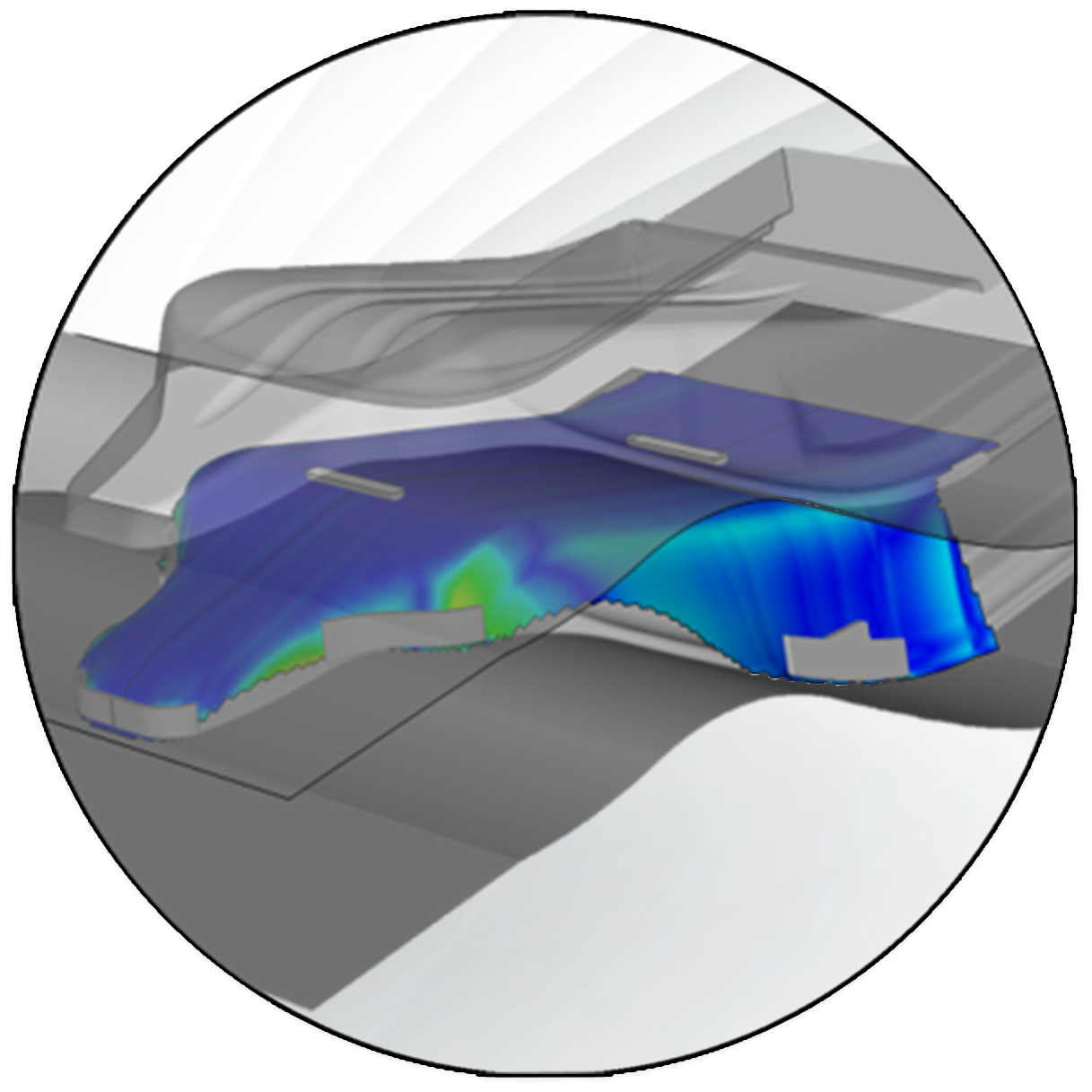

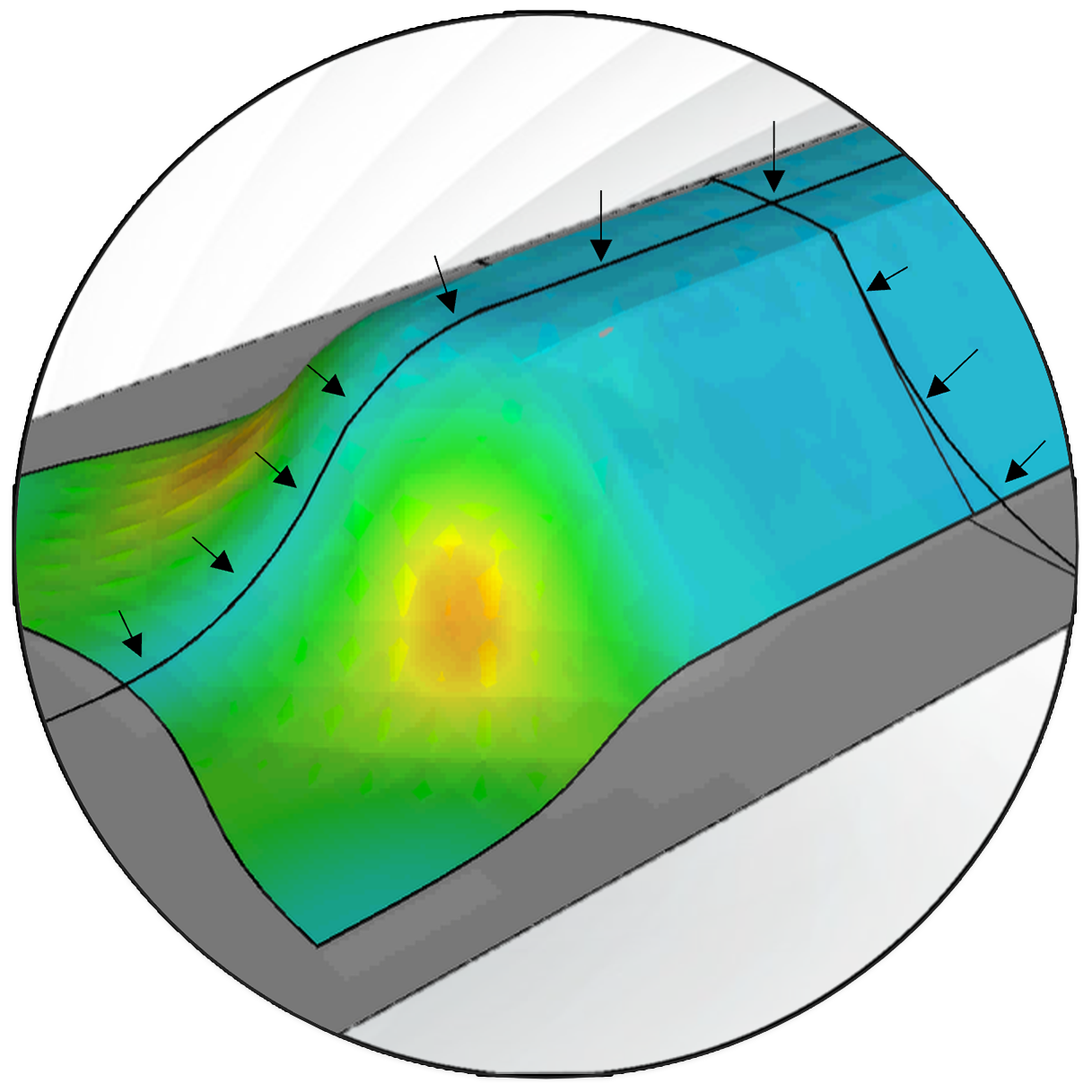

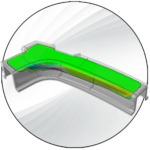

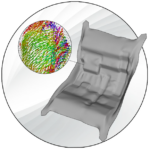

Forming two-dimensional semi-finished products into complex shapes is one of the most determining process steps in the manufacturing of continuously fiber-reinforced plastics.

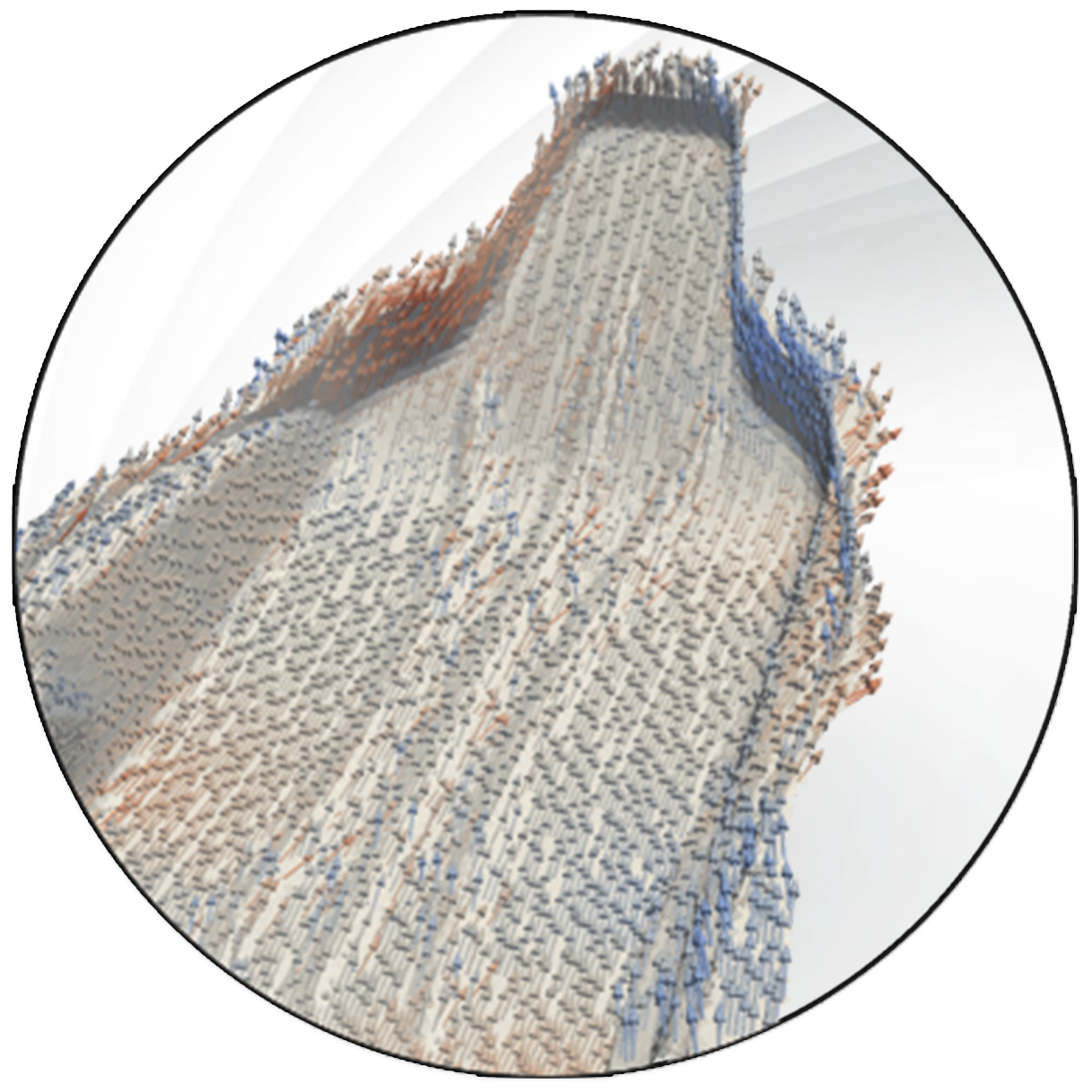

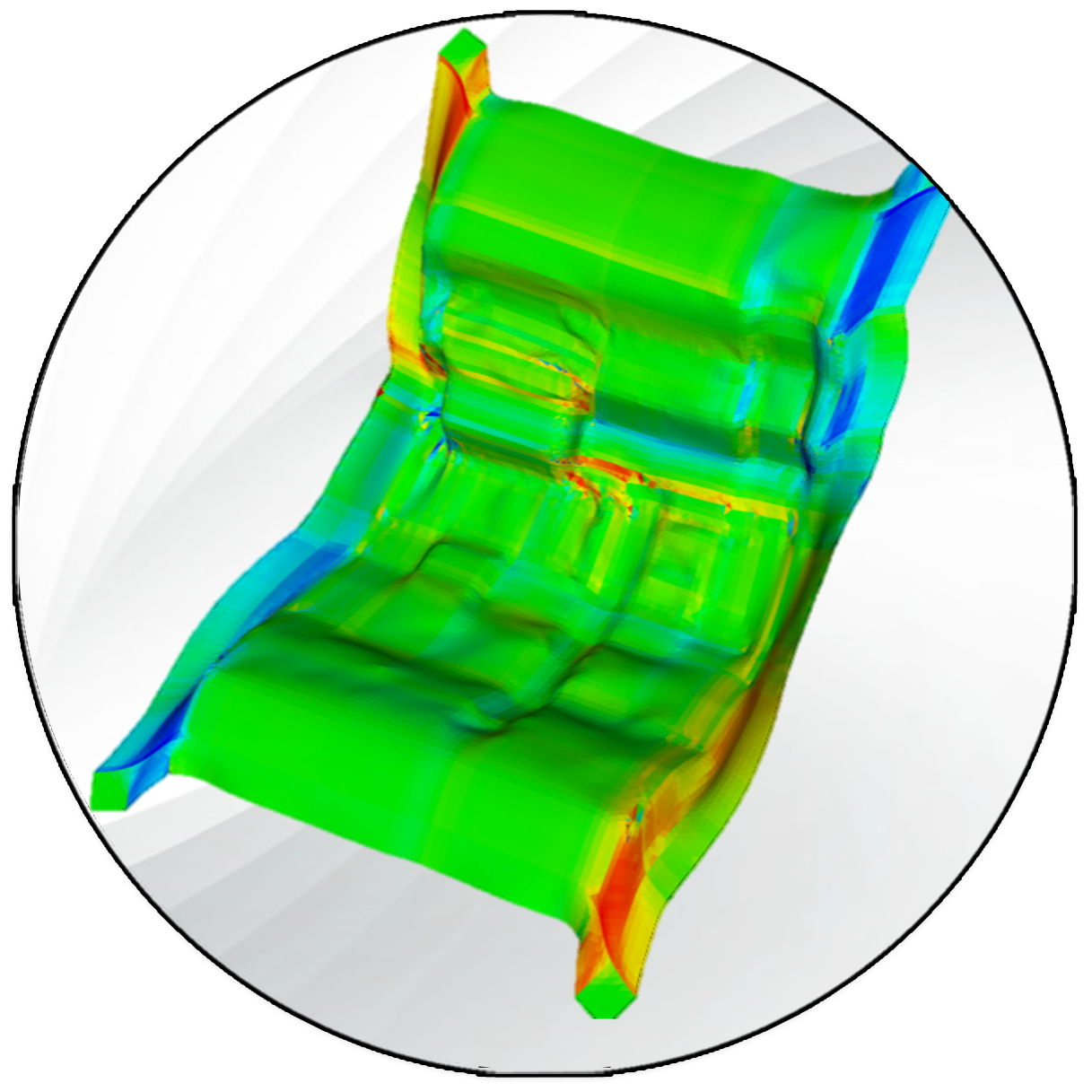

Forming might be accompanied by forming defects like local wrinkling or gapping. Moreover, forming effects, including a change in fiber orientation or fiber volume content, are inevitable.