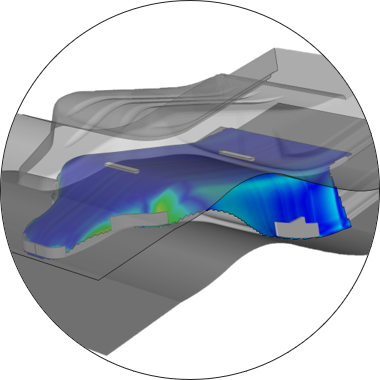

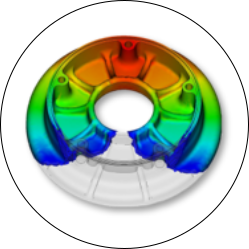

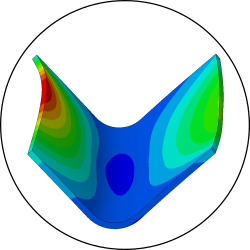

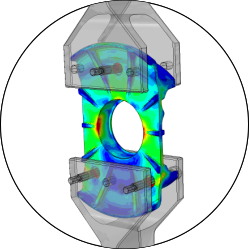

Composite forming

- Validation of manufacturability

- Optimization of gripper, clamping, and sequential forming setups

- Support of mold design

- Prediction of local fiber orientation and fiber volume content

- Thermomechanical-thermokinetical analysis for thermoforming

- Supported technologies: Thermoforming, textile draping, membrane forming, and hot forming

- Material card creation as a service