SimuChain, our add-on for Abaqus, creates a virtual process chain and enables us to consider manufacturing effects in structural simulation. We support structural analyses for chopped fiber materials (SMC, LFT, GMT) and continuously fiber-reinforced composites including nonlinear material modeling under quasi-static loading conditions.

The Abaqus/CAE plugin of SimuChain enables the preprocessing of data exported from process simulation (Moldflow, SimuDrape, SimuFill) as well as the generation of homogenized and clustered material cards for chopped fiber materials and composite layups for continuously fiber-reinforced composites.

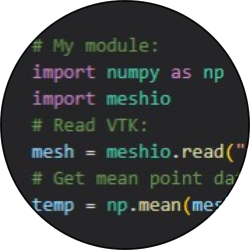

The SimuChain backend can be called through the Abaqus Python API. Based on this, you can implement your own scripts and model automation. This includes data assessment through our meshio backport as well as mapping of discretized data through MpCCI MapLib.

Short video: Virtual process chain for SMC.

Key features

Mapping

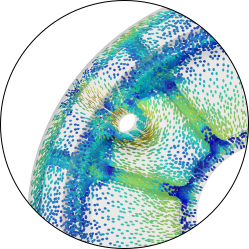

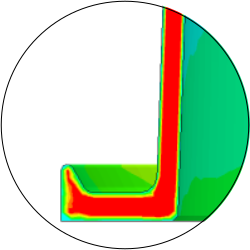

SimuChain uses MpCCI MapLib to map scalars, vectors, and tensors between meshes. Based on this, the transfer of manufacturing effects such as the local fiber orientation predicted by composite forming simulation to e.g. structural simulation is enabled.

Composite layup

Composite forming simulation is capable to predict the fiber orientation of a stacked laminate layer by layer. SimuChain enables the mapping of the local fiber orientation onto the mesh of a structural simulation (FEA) and into a composite layup to efficiently model the mechanical behavior of a laminate under consideration of the local anisotropy.

Homogenization

Compression and injection molding simulation are capable to predict the flow-induced local fiber orientation. SimuChain enables the mapping of the local fiber orientation onto the mesh of structural simulation (FEA) and homogenizes and clusters the effective material properties. This requires the definition of the properties of the fibers, matrix, and composite. Based on this, the flow-induced local anisotropy can be considered.

Field initialization

Process simulation predicts a variety of state variables. This is valid in particular while working with SimuDrape and SimuFill, which enable the prediction of crystallization and curing kinetics. SimuChain enables the initialization of those state variables for subsequent simulation steps. This feature is used for instance in SimuWarp.

Data processing

Moldflow uses its own file format for the export of state variables. SimuChain enables the transformation of the data exported from Moldflow into the neutral file format VTK, which can be visualized in the open-source software Paraview and processed through Python package meshio.

Data assessment

Our meshio modification (backport) enables its usage in Abaqus/CAE. Meshio is a powerful tool for reading and writing mesh-based data and therefore serves as the basis for data assessment using Python scripting.

Related Case Study

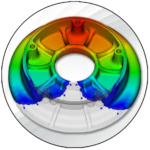

Virtual Process Chain for SMC Materials

In a collaboration project with Blackwave, the Simutence virtual process chain for SMC materials has been validated for the rim of a lightweight airplane.

Simutence uses an in-mold characterization approach to accurately characterize both the viscosity and the wall slip of the SMC. The acquired data is used to parameterize flow models built into commercial molding simulation software, such as Moldflow.

Any questions?

Interested in a trial license?

Do not hesitate to get in contact with us. We are pleased if you leave us a message!