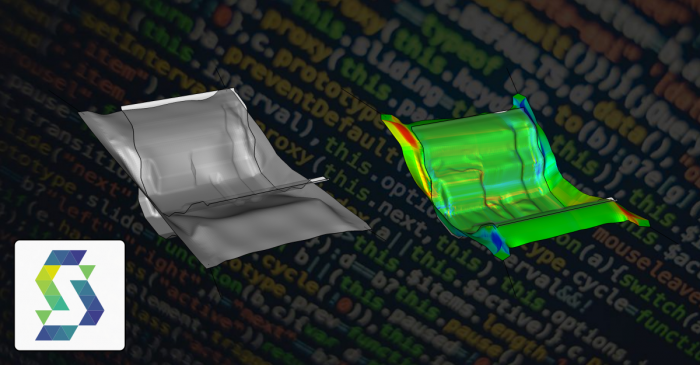

Advanced composite forming simulation enables to predict and optimize the manufacturability for forming processes of continuously fiber-reinforced composites. Moreover, manufacturing effects, such as the influence of the forming process on the fiber structure, are predictable.

Through consideration of manufacturing effects within a virtual process chain, the prediction of warpage and structural simulation is significantly increased.

A few weeks ago, we signed a license agreement with KIT. This license agreement grants us to use the simulation methods we developed during our doctoral studies. The related simulation approaches for process and structural simulation of fiber-reinforced composites include also the advanced composite forming simulation.

Our approach for composite forming simulation uses Abaqus in combination with add-ons for pre- and postprocessing, as well as for the advanced material modeling. Thus, existing software infrastructures can be adopted.

We worked hard, to make these methods ready to be used by our partners. The further developments included the creation of a User’s Guide, verification tests to guarantee a high source code quality, as well as the improvement of the user-interfaces.

Now, we are delighted to have our first product – SimuDrape – ready to be supplied to our partners!

Already last year, we held several workshops to give some of our partners an introduction into composite forming simulation and the use of SimuDrape. Currently, several partners are benchmarking SimuDrape for their applications within a trial period with our support for material characterization and material modeling.

In the next weeks, we plan to use the slowdown of daily business due to the corona crisis to further develop SimuDrape for the application to a larger variety of different thermoplastic tape materials. We will emphasize thermomechanical analysis techniques, in combination with crystallization kinetics modeling. Including this has proven to significantly improve the prediction accuracy of thermoforming defects, such as wrinkling behavior.

Stay tuned! We will keep you updated!

If you are interested in more details, a live demonstration, or a trial license, please do not hesitate to get in touch with us: