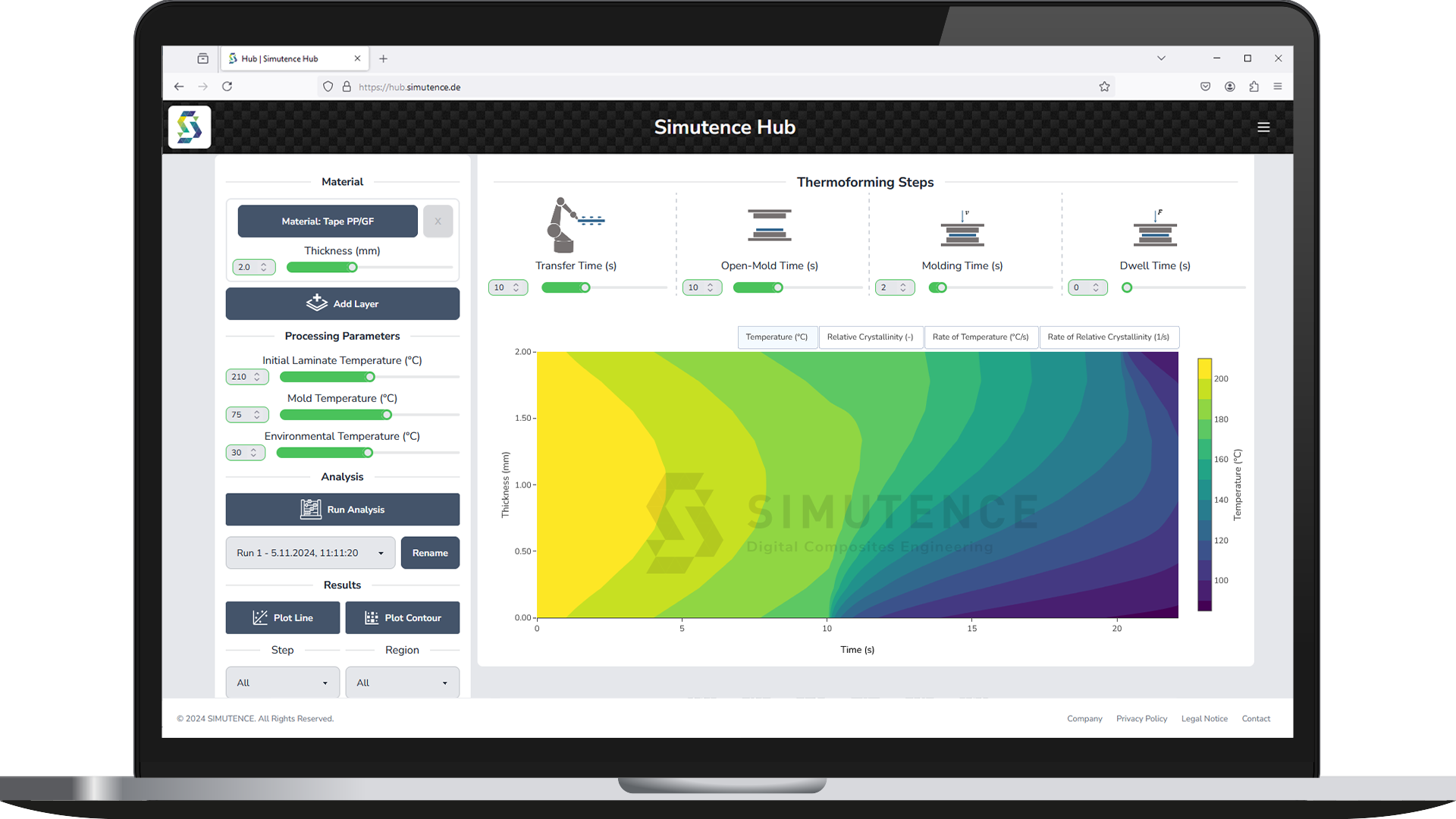

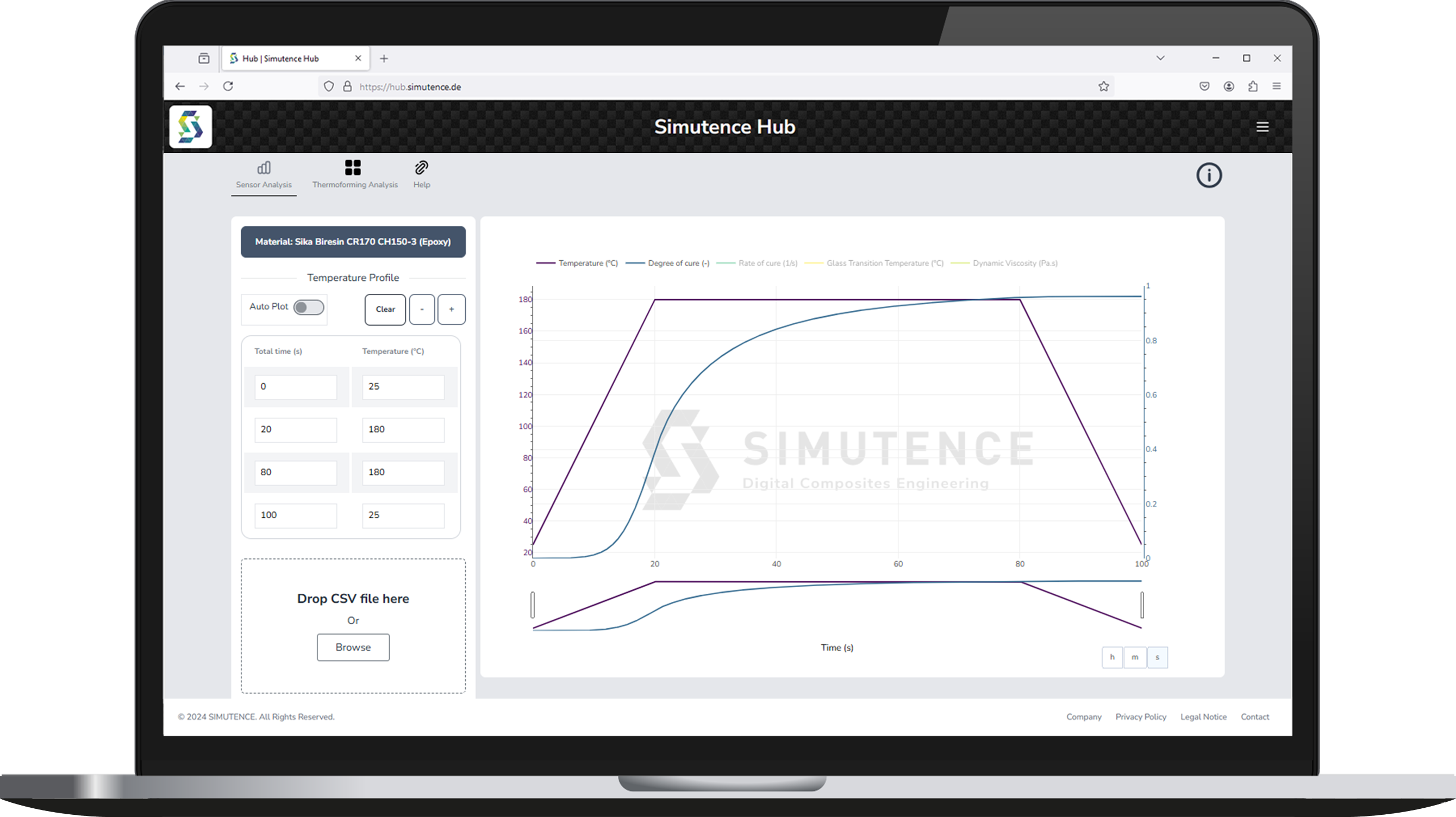

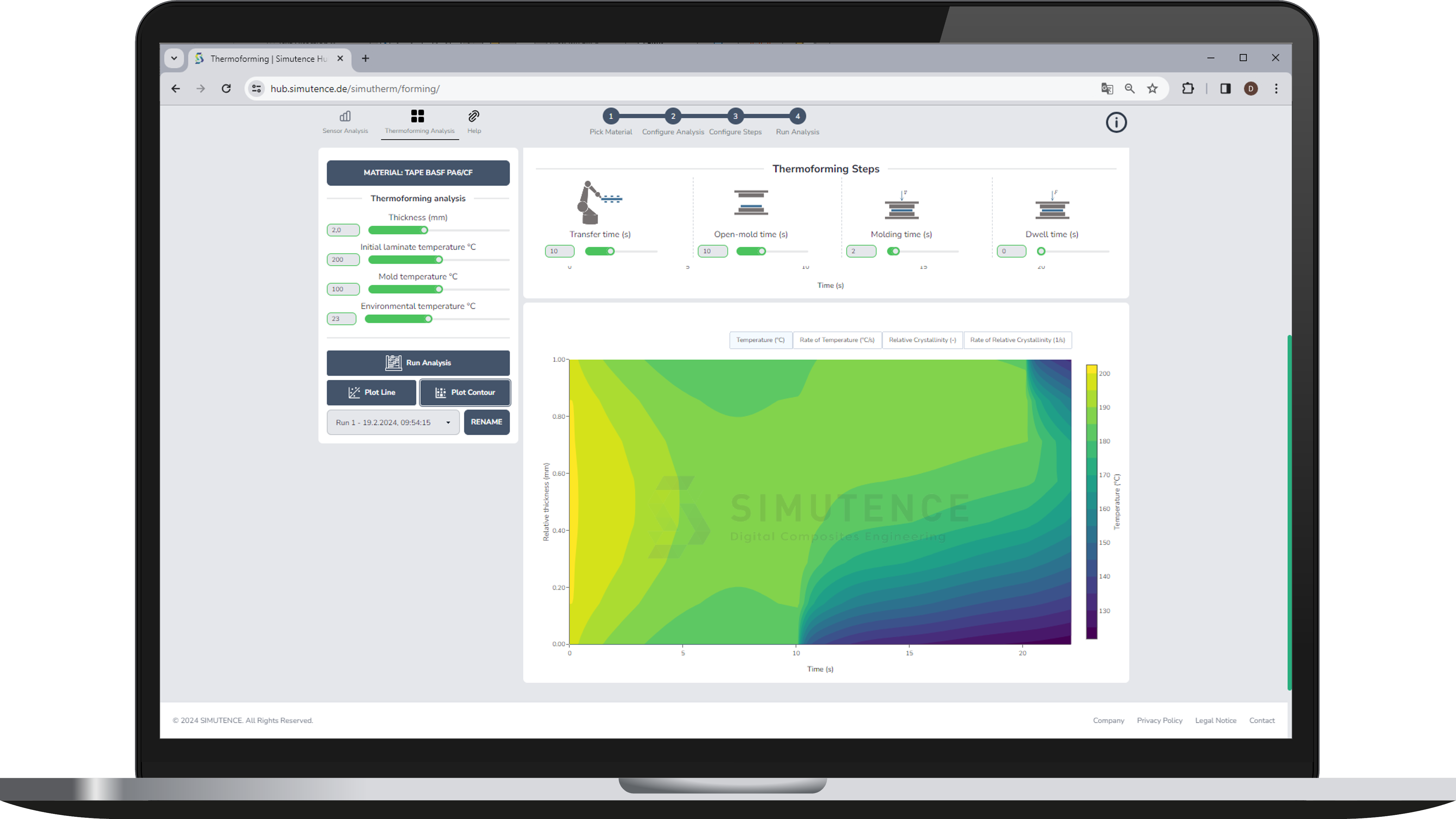

Optimize manufacturing process in real-time

SimuTherm enables real-time thermokinetic analyses of manufacturing processes and is available as a web application through our Simutence Hub. The web application is intended to be used by both simulation laymen and simulation experts.