A combination of thermoplastic tapes with long fiber-reinforced thermoplastics (LFT) in overmolding processes further enables increasing the lightweight potential through local functionalization and geometric stiffening. High production costs and limited understanding of large-scale-specific processes, however, still hinder high-performance composites to enter the mass-production market.

This challenge can be met through a continuous and functional virtual process chain. Manufacturing simulation enables the optimization of manufacturing processes and the integration of process simulation into a holistic virtual process to predict dimensional stability and structural performance.

For sequential overmolding processes, however, no out-of-the-box approaches for process simulation exist. Therefore, Simutence and KIT-FAST presented in a joint contribution at the ITHEC conference 2022 an own approach, using SimuDrape for thermoforming simulation and Moldflow for subsequent injection molding simulation. This approach is outlined briefly in the following.

Part design

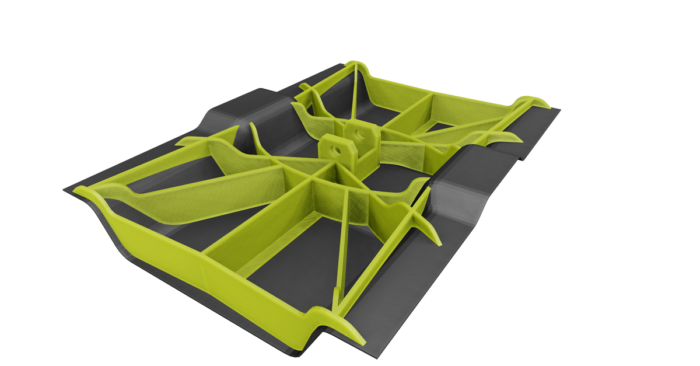

A demonstrator geometry comprising a thermoplastic tape laminate with moderate complexity, as well as overmolded and complexly shaped ribs for geometric stiffening was developed, to demonstrate the overmolding process simulation approach. The geometry is inspired by the demonstrator part of the COMPeTE II project carried out at the thermoplastic composites research center (TPRC).

CAD design of the overmolded geometry comprising a thermoplastic UD-tape-laminate (grey) and overmolded ribs (yellow).

For this study, topology optimization was used to determine a suitable rib structure. The tape material is considered a non-design space, and the optimization is applied to the LFT design space. The adopted optimization goal is the minimization of global compliance with simultaneous reduction of the LFT.

The resulting topology optimizations are assessed successively and transferred to the final CAD design in an engineering step.

left: Topology optimization loadcase 1

right: Topology optimization loadcase 2

Thermoforming simulation

A fully coupled thermomechanical approach predicting the temperature evolution and crystallization kinetics is applied for thermoforming simulation. Based on this, the phase transition from the molten to the solid material state is predicted and considered in the temperature- and rate-dependent thermoforming behavior. This approach was originally developed at the Karlsruhe Institute of Technology (KIT, Germany) and is now supplied by SIMUTENCE through SimuDrape, which comes as an add-on for the finite element software ABAQUS/CAE and ABAQUS/Explicit.

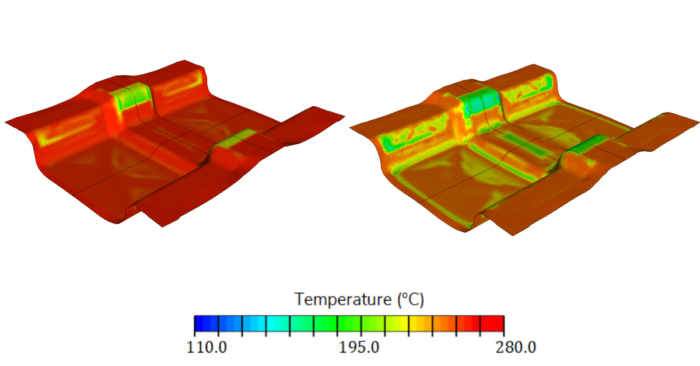

For the thermoforming simulation of the PA6-CF tape, a tool temperature of 110 °C and an initial laminate temperature of 280 °C is assigned. For material modeling, an existing material card, which has proven a high prediction accuracy in previous studies, is adopted.

The thermoforming simulation results reveal the overall good formability of the orthotropic layup. Regarding the thermal behavior, only slight temperature changes are observed at the free surfaces due to convection and radiation. In contrast, the tool-ply contact renders a significant temperature profile onto the laminate.

The press profile is one of the major process settings and needs to be defined depending on the formed geometry and the press used. Therefore, slow and fast press profiles were investigated. It is observed that temperatures slightly below 200 °C are observed for the fast press profile, whereas temperatures close to the tool temperature are observed for the low forming speed.

Temperature distribution at the moment of full tool closure: Fast (left) and slow press profile (right).

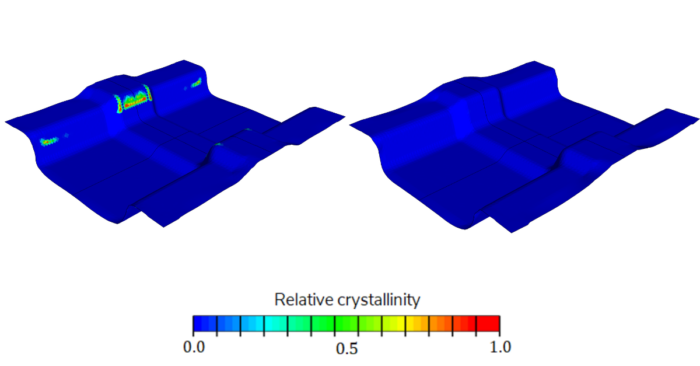

Based on this, local recrystallization is observed in the areas of pronounced cooling. Thus, manufacturing defects, poor part quality, and material failure are to be expected in these areas since the material has solidified already during forming. In contrast, no recrystallization is observed for the high forming speed. Therefore, a comparably fast press profile is to be preferred for this geometry.

Relative crystallinity distribution at the moment of full tool closure: Fast (left) and slow press profile (right).

Overmolding Simulation

The proposed approach for overmolding simulation covers a sequential process route, where the process steps thermoforming and overmolding are conducted one after the other. Therefore, the tape is considered as a part insert for the injection molding simulation conducted in Moldflow.

There are two major perspectives by using this overmolding simulation approach. First, the filling behavior, including the influence of related processing parameters, is to be predicted. Second, the minimum preheating temperature and time for the tape to achieve a high interface strength between the tape and the LFT is to be predicted.

Previous studies have proven that a fully molten interface is required to obtain a high interface strength. Therefore, the heat balance equation is solved for the LFT and the tape in the overmolding simulation, and the temperature evolution in the interface between LFT and tape is evaluated.

Temperature distribution tape after overmolding and positions of local temperature evaluations.

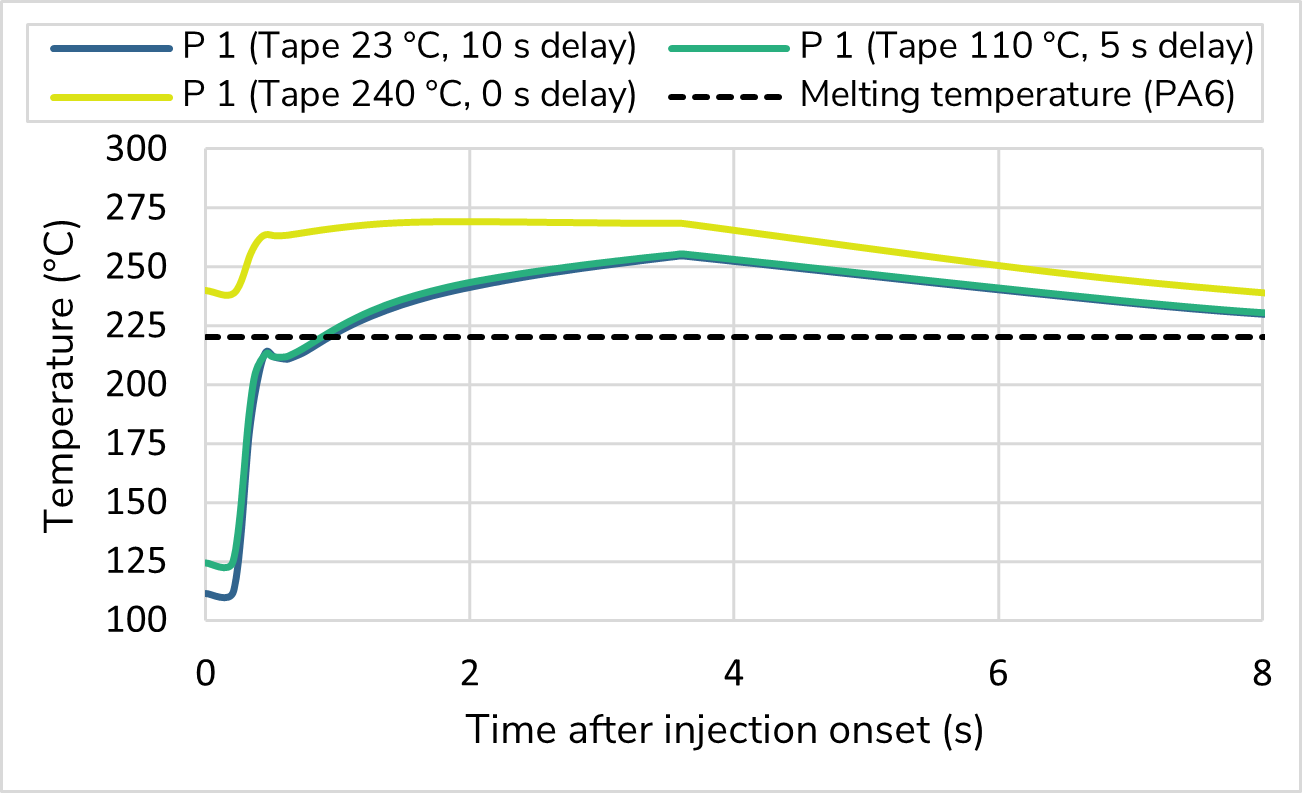

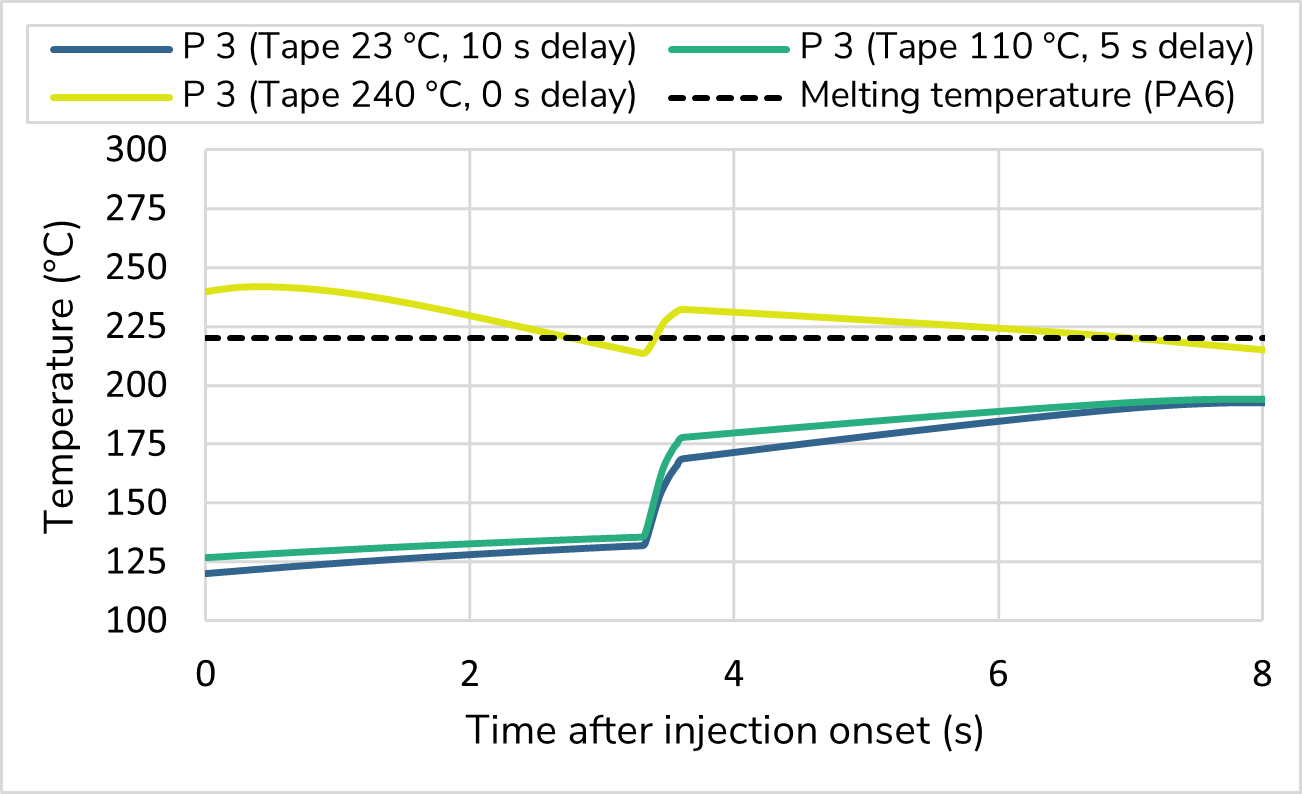

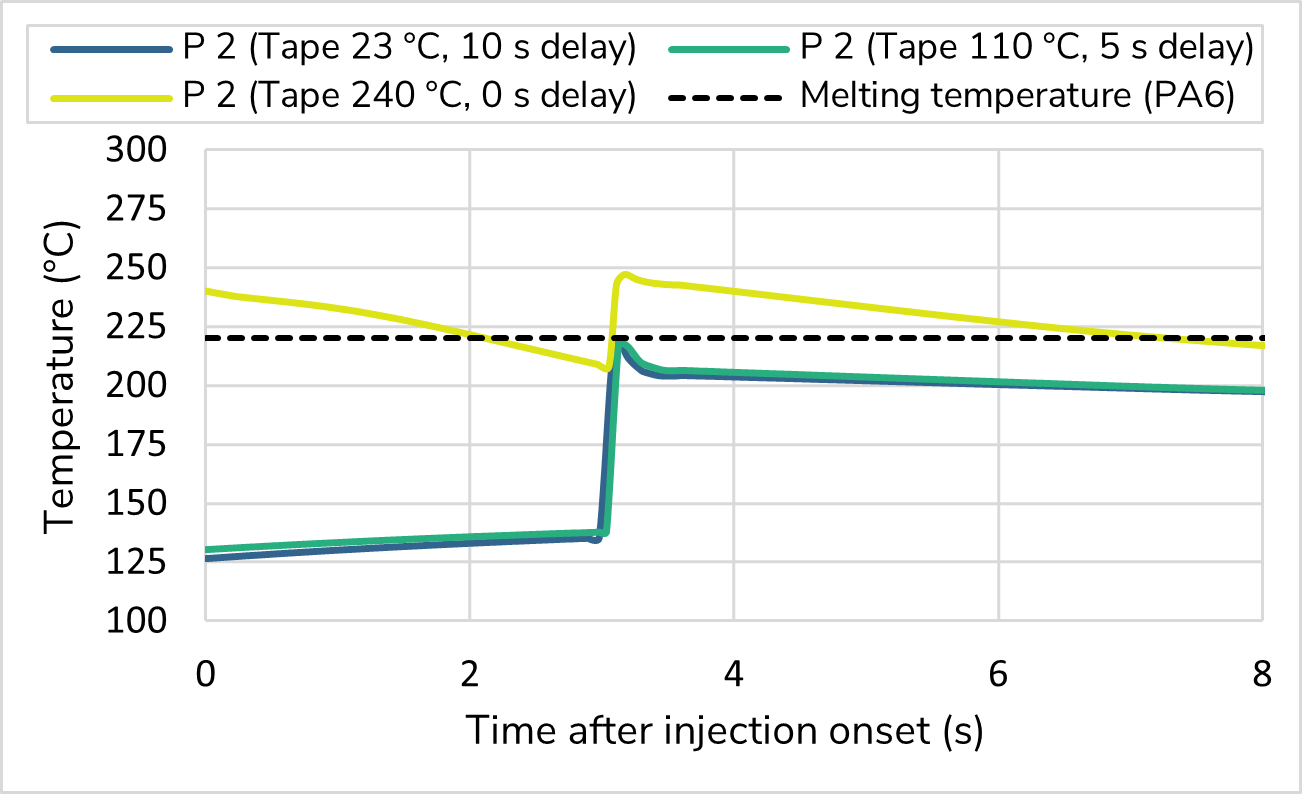

In the scope of this study, the tool temperature is varied between 80 °C and 150 °C, while three different tape temperatures (23 °C, 150 °C, and 240 °C) are considered. Furthermore, the time delay between cavity closing and onset of overmolding is varied between 0.0, 5.0, and 10.0 s.

For the investigated scenarios, it is observed for position 1 (P1) that the interface temperature is higher than the melt temperature, even for a tape that is not pre-heated. Thus a high interface strength is to be expected for all variants. For the remaining positions (P2 & P3) further away from the injection point, in contrast, a pre-heating of the tape is required to reach the melting temperature in the interface. However, an external pre-heating can be prevented if the cycle times allow an internal pre-heating within the cavity, which is reflected through the time delay.

Interface tempeature at P1

Interface temperature at P3

Interface tempeature at P2

Conclusion

The overmoldig of thermoplastic tape laminates with LFT can serve as an enabler for high-performance composites in large-volume production since the LFT enables local functionalization as well as geometric stiffening.

In this study, we have shown that topology optimization can be powerful for the determination of a suitable rib structure. Moreover, the proposed sequential simulation approach is straightforward to be adopted by existing simulation techniques, namely SimuDrape for thermoforming simulation and Moldflow for subsequent overmolding.

Based on this, thermal history is predicted along the sequential process route, where the thermoformed tape laminates serve as an insert for overmolding. Thereby, the prediction of the temperature evolution in the interfaces enables to determine suitable processing parameters in terms of internal and external pre-heating to guarantee a high interface strength.

As a next step, the temperature profile predicted by the thermoforming simulation will be transferred as the initial situation to the overmolding simulation. Based on this, also one-shot processes, where the tape laminate is formed and overmolded in a single step, can be considered.

References

- M. Hohberg, D. Dörr, B. Fengler, C. Krauss, N. Meyer, L. Kärger, F. Henning: Integrated process simulation as key for the efficient product and process development, ITHEC 2020 – Virtual Edition, 13.-15.10.2020.

- D. Dörr: Simulation of the thermoforming process of UD fiber-reinforced thermoplastic tape laminates. Doctoral studies. Karlsruhe Institute of Technology, Karlsruhe. Institute of Vehicle System Technology, 2019.

- Rausch, Julius, Kugele, Daniel (2016): Temperature Monitoring of Thermoplastic Laminates in an Automated, SAMPE Europe Conference 2016

Any questions?

Do not hesitate to get in contact with us if you have any questions or if you are interested in a collaboration. We are pleased if you leave us a message!